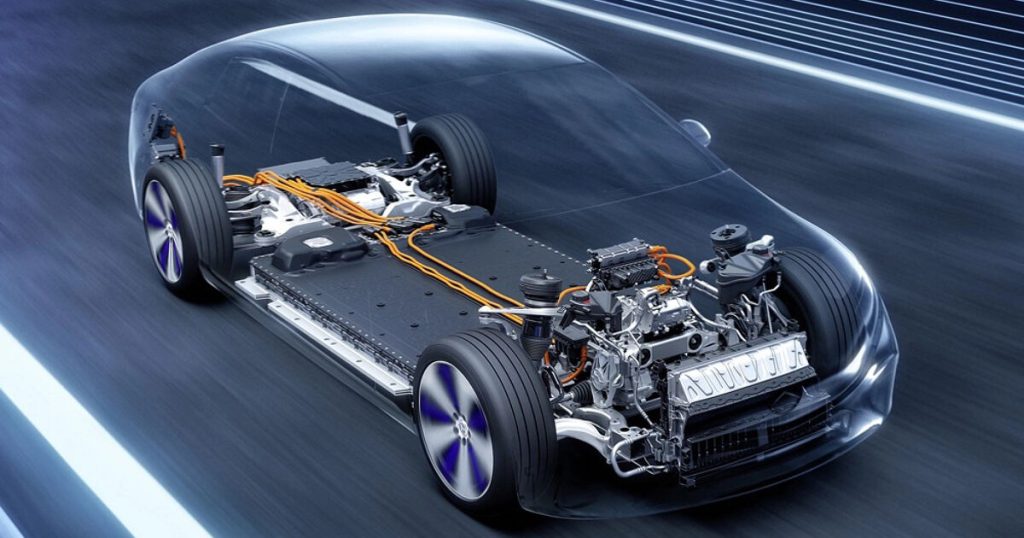

in Europe Will it be To elect to Electrical engine binding For new cars from January 1, 2035. this the shift will extremist It is irreversible, as specified in stone. Of course, cars with combustion engines will still be able to drive, but they will likely disappear very quickly, because it is logical to expect that traffic restrictions will apply to them.

However, there is border value Europeans No invoice It has been taken into account: delivery by Basic minerals to Batteries. This came in A modern one research For the independent organization Transport and environment (T&E), which showed that European automakers Less than one-fifth Of quantities Cobalt, Lithium And Nickel Necessary to achieve sales goals for 2030.

Advertisement – Read more below

Serious problem?

This situation would affect the position European automobile manufacturers Can again weakens. Although the authorities and manufacturers are trying… Bringing battery production back home To the Old Continent (just think of the Auto Cell Company’s factory in Dunkirk), these factories must of course be supplied with raw materials. This doesn’t seem very clear. the Situation It seems more than that More clown Because manufacturers love Tesla I took the lead long ago, instead Chinese Control the entire value chain, from raw material extraction to battery production.

Accurate evaluation

To this Unfortunate find to come, Evaluated Transport and environment general Tenders And Rank Manufacturers According to its supply chain, specifically in the field of batteries. Analysis shows this European manufacturers like Volkswagen And Stellantis progress Books in this area, but that of all the others lagging behind a lot.

According to T&E, brands like Tesla And BYD more Control their future Because they have better control over their supplies, but the organization points out that At the expense of environmental practices Which is often questionable. However, T&E notes that Tesla, BYD, VW, Ford, Renault and Stellantis all Long term contracts They contain cobalt, lithium and nickel for each of the three main metals, but brands are also working to replace these materials with new chemicals. The problem is that developments take time and lead times are (very) short.

Are the Europeans leading the way?

as Europeans that precedence They have over their American and Chinese competitors, but only in this area Sustainability And respect Social rights Across the battery value chain. T&E refers to better traceability of materials, but also to respect for human rights and care of a Small environmental footprint During the industrial process. Here also lie the advantages of the electric car: respect for global ethics.

Finally, Transport and Environment confirms this fact A few European manufacturers I work with Start-ups Or companies specializing in battery components or metal processing. This is for analysts Situation worryingBecause it exposes our manufacturers to greater risks, especially at a time when… Tensions between China and the West He increases. T&E reports that Demand for lithium From now until 2030 Quadrant And that by then he was already there Lack Expected (about 390,000 tons). So there it is European mining projects necessary. But it takes a long time to get it ready, at least 5 years It takes a long time before a project with an industrial dimension takes shape. time is running out.

it’s clear Manufacturers As a whole Memory is short We have, because we must not forget that Chip shortage That hit us in 2020 was actually a result of Lack of anticipation and security of supply. Must history repeat itself?

Looking for a car? Search, find and buy the best model on Gocar.be

What will your next car be?

“Coffee buff. Twitter fanatic. Tv practitioner. Social media advocate. Pop culture ninja.”

More Stories

Strong increase in gas export pipeline from Norway to Europe

George Louis Bouchez still puts Julie Tatton on the list.

Thai Air Force wants Swedish Gripen 39 fighter jets